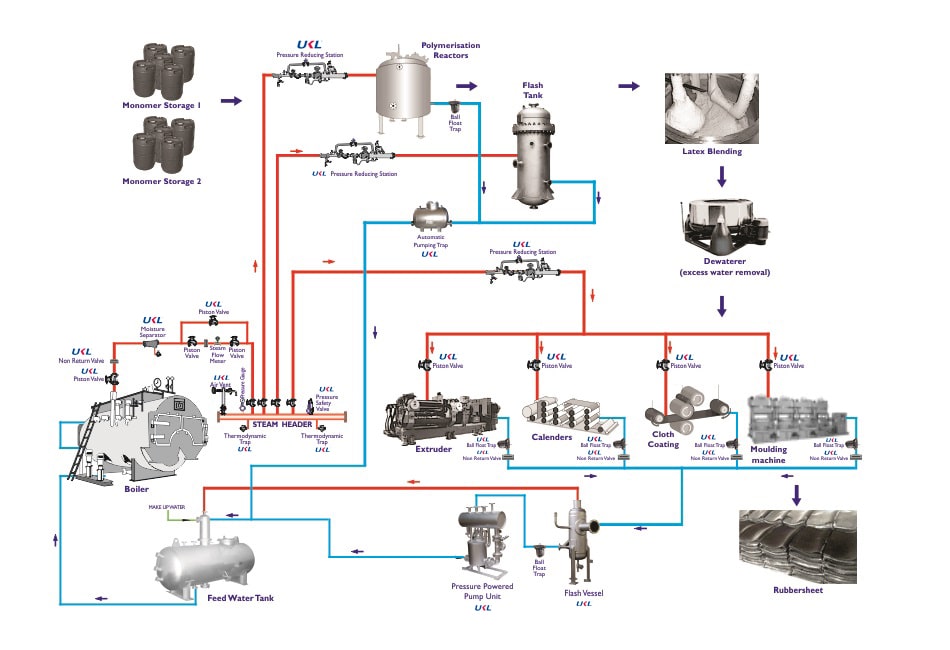

Compression moulding is the most common moulding technique used in the rubber industry. It involves pressing uncured rubber between heated moulds so that the rubber compound first fills the mould cavity before curing to produce finished article. The presses are usually pneumatically or hydraulically powered and the mould can be heated by steam. UKL delivers steam valves and other accessories used in the rubber industry.

- Home

- About UKL

-

Products

- Fluid Control Division

- Fluid Sealing Division

- Safety Valve & Control Valve Division

- Steam Engineering Services

- Solutions

- Ask the Expert

- Company Updates

- Career

- Contact Us

- Enquiry

- Home(current)

- About UKL

-

Products

- Fluid Control Division

- Fluid Sealing Division

- Safety Valve & Control Valve Division

- Steam Engineering Services

- Solution

- Ask the Expert

- Company Updates

- Career

- Contact Us

- Enquiry

Aerated Concrete Block Industry

Aerated Concrete Block Industry  Brewery Industry

Brewery Industry  Captive Cogen Industry

Captive Cogen Industry  Chemical Industry

Chemical Industry  Dairy Industry

Dairy Industry  Edible Oil Industry

Edible Oil Industry  Fertilizer Industry

Fertilizer Industry  Hotel Industry

Hotel Industry  Pharma Industry

Pharma Industry  Rice Industry

Rice Industry  Rubber Industry

Rubber Industry  Soap Industry

Soap Industry  Sugar Industry

Sugar Industry  Textile Industry

Textile Industry  Tyre Industry

Tyre Industry